Problem

A large University in the Nation’s Capital underwent an upper level fit-out over occupied classrooms while school was in session. As you can imagine this presented many obstacles to overcome. The new area consisted of BSL-3 labs, animal holding and agricultural research. The University wanted a flooring surface suitable for a BSL-3 environment that also incorporated a waterproof membrane, 8” cove base, chemical resistance, low odor & aesthetically pleasing properties. After our pre-site inspection we noticed a number of control joints and spider cracking in the existing substrate that needed to be addressed as well.

Solution

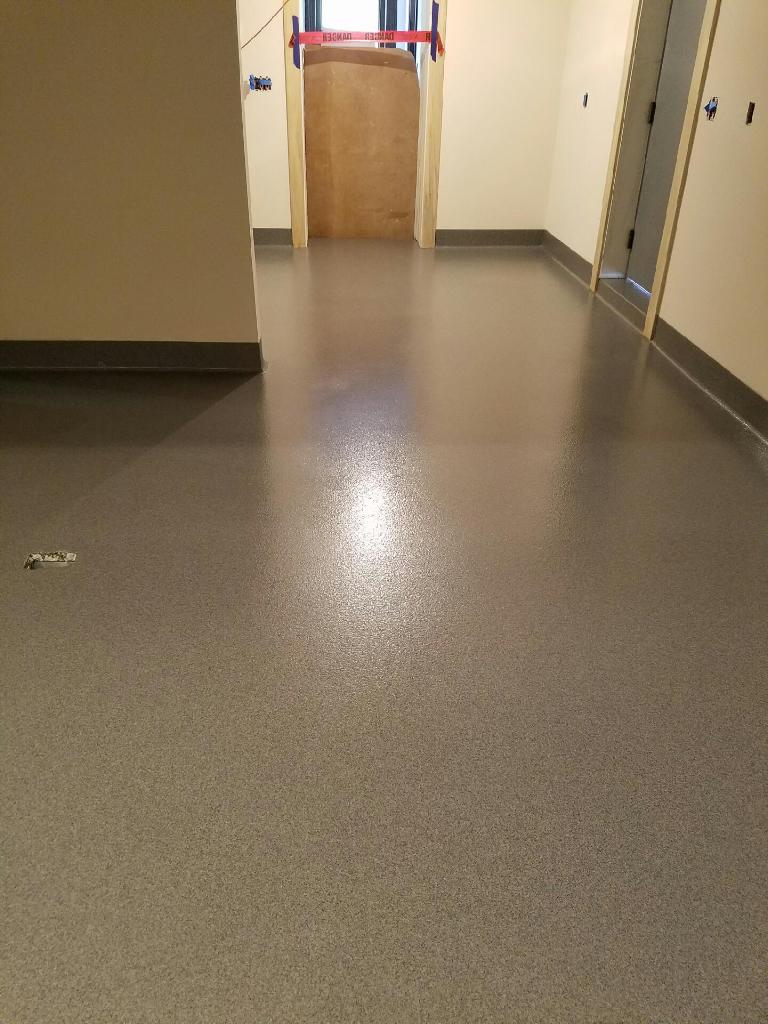

Durex first mechanically prepared the floor, exposing all cracks and providing the acceptable profile for our system. After pre-filling the control joints & cracks we inlayed fiberglass scrim at the joints to help mitigate movement. Our crew then installed a low odor floor systems that combines flexible waterproof epoxy for crack isolation and colored quartz aggregate for a tough decorative finish. Finally we sealed the system with a chemical resistant topcoat to withstand the harsh laboratory environment.